Large Fiberglass Statue of Liberty | Custom Replicas

In the realm of large-scale artistic and architectural installations, fiberglass has emerged as a revolutionary material, offering unparalleled versatility, durability, and cost-effectiveness. The ability to craft intricate details and monumental sizes makes it the material of choice for everything from commercial mascots to public art. One of the most ambitious and symbolically significant projects that could leverage this technology is a **fiberglass statue of liberty**, allowing for replicas of varying scales or even reinterpretation of iconic structures. This comprehensive guide explores the fascinating world of large fiberglass sculptures, delving into industry trends, technical specifications, manufacturing processes, and practical applications, enhancing your understanding of why fiberglass is redefining the landscape of monumental art.

Product Highlight: Garden Decorative Life Size Fiberglass Elephant Sculptures Resin Animal Sculpture For Sale

While this article explores the general advancements in fiberglass sculpture, including monumental pieces like a **fiberglass statue of liberty**, our expertise extends to a wide array of custom projects. Discover our exquisite Garden Decorative Life Size Fiberglass Elephant Sculptures Resin Animal Sculpture For Sale, a testament to the precision and artistry achievable with modern fiberglass techniques.

Industry Trends and the Rise of Fiberglass in Public Art

The global market for large-scale sculptures is witnessing a significant shift towards composite materials, particularly fiberglass. Traditional materials like bronze, marble, and concrete, while timeless, often come with prohibitive costs, weight issues, and complex installation challenges. Fiberglass, or Fiber Reinforced Polymer (FRP), addresses these concerns by offering an optimal balance of strength, lightweight properties, and malleability. Current trends indicate a surging demand for:

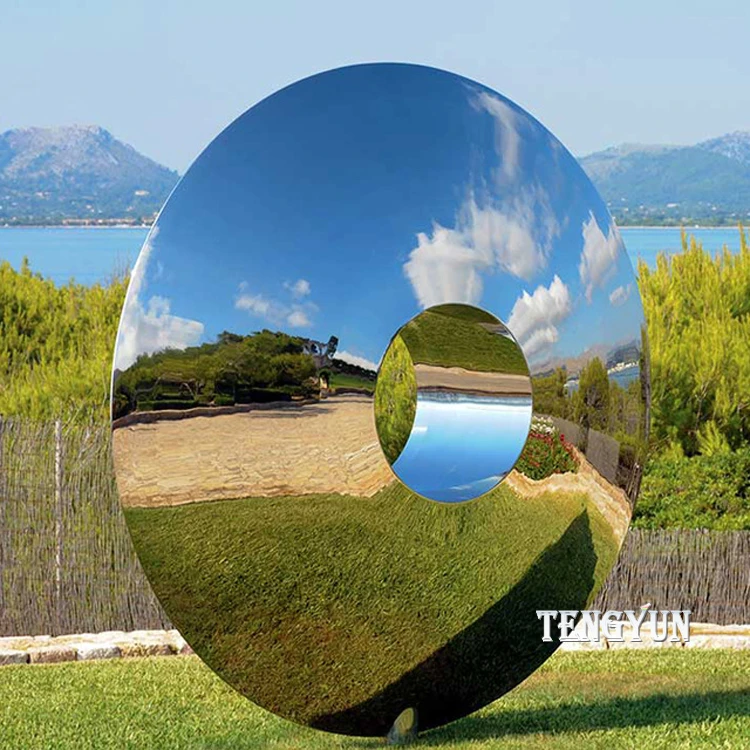

- Public Art Installations: Cities and private developers increasingly commission large fiberglass statues for parks, plazas, and urban regeneration projects due to their weather resistance and ease of maintenance.

- Commercial Branding & Theme Parks: Brands seek eye-catching, durable mascots and thematic elements. Theme parks rely heavily on fiberglass for immersive environments and character representations, from whimsical figures to monumental structures like a **fiberglass statue of liberty** replica for a specific attraction.

- Architectural Accents & Facades: Architects are utilizing fiberglass for lightweight, custom-shaped facades and decorative elements that would be impractical or too heavy with other materials.

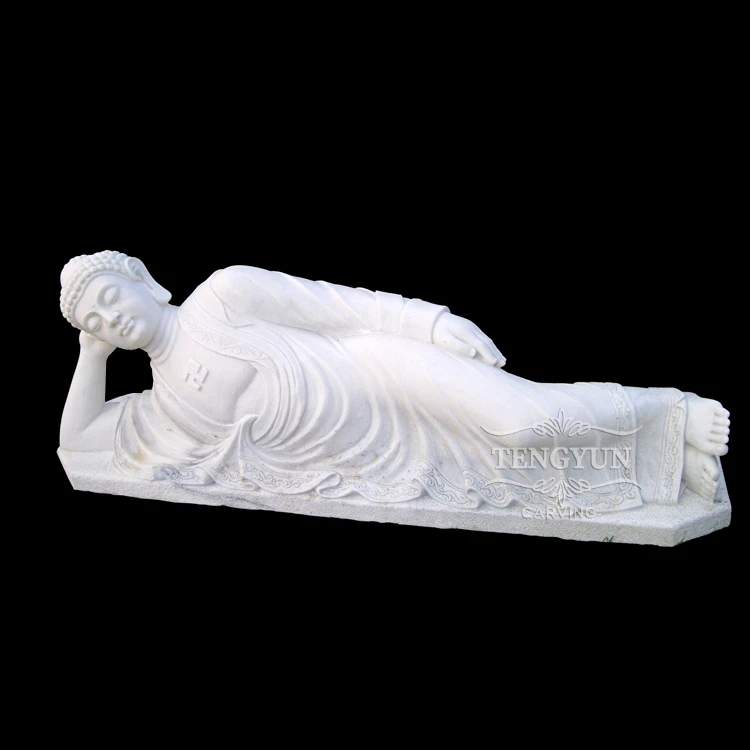

- Cultural & Religious Icons: The demand for large fiberglass Buddha statue and similar religious or cultural figures is growing, especially where traditional materials are scarce or conservation is a concern.

This trend is supported by data from industry reports, which project a compound annual growth rate (CAGR) of over 6% for the global composites market in art and construction applications through 2028, largely driven by fiberglass innovations (Source: Grand View Research, 2021). The ease of transportation and installation, coupled with extended lifespan and reduced maintenance, makes fiberglass an economically sound choice for long-term outdoor installations.

Technical Parameters and Superiority of Fiberglass

Fiberglass is a composite material made of glass fibers embedded in a resin matrix, typically polyester, vinyl ester, or epoxy. This combination yields a material with an exceptional strength-to-weight ratio, surpassing steel in some applications. Its technical parameters make it highly suitable for outdoor and high-stress environments:

- Density: ~1.8-2.0 g/cm³, significantly lighter than steel (7.85 g/cm³) or concrete (2.4 g/cm³). This lightness drastically reduces shipping and installation costs, as well as structural foundation requirements.

- Tensile Strength: Can range from 150 MPa to 500 MPa, depending on fiber content and resin type. This allows for slender designs without compromising structural integrity.

- Corrosion Resistance: Excellent resistance to water, chemicals, acids, and alkalis. This is crucial for outdoor installations in diverse climates, from coastal regions (salt spray) to industrial areas (pollutants). Applicable industries include petrochemical, marine, and public infrastructure.

- UV Resistance: When formulated with UV inhibitors in the gel coat or paint, fiberglass offers superior resistance to degradation from sunlight, preventing fading and material breakdown.

- Temperature Stability: Capable of withstanding a wide range of temperatures, typically from -40°C to +80°C, without significant structural deformation or material degradation.

- Moldability & Versatility: Can be molded into virtually any shape or texture, allowing for high fidelity to artistic designs, whether it's the flowing drapery of a **fiberglass statue of liberty** or the textured hide of an elephant.

- Lifespan: With proper manufacturing and maintenance, large fiberglass statues can have an outdoor lifespan exceeding 20-30 years, often outperforming traditional materials in harsh conditions.

Comparative Analysis: Fiberglass vs. Traditional Materials

To further illustrate the advantages, here's a comparison highlighting key aspects:

| Feature | Fiberglass (FRP) | Bronze | Stone (e.g., Marble) |

|---|---|---|---|

| Weight | Very Light (Easy Transport/Installation) | Very Heavy (Complex Logistics) | Extremely Heavy (Requires Robust Foundations) |

| Corrosion/Weather Resistance | Excellent (UV, water, chemical resistant) | Good (Patina forms, can corrode) | Fair (Porous, susceptible to acid rain & erosion) |

| Moldability/Detail | High (Any shape, intricate detail) | Good (Casting limits detail, high cost) | Limited (Carving, susceptible to breakage) |

| Maintenance | Low (Wipe clean, occasional recoat) | Moderate (Waxing, cleaning, anti-corrosion) | High (Cleaning, sealing, repair) |

| Cost (Manufacture & Install) | Moderate to High (Initial) / Low (Long-term) | Very High | Very High |

| Lifespan (Outdoor) | 20-30+ years (with proper coating) | 50-100+ years (with consistent care) | 50-100+ years (but prone to erosion/cracking) |

| Energy Efficiency | Minimal thermal conductivity (insulative) | High thermal conductivity | Moderate thermal conductivity |

This data clearly demonstrates fiberglass's technical superiority for many modern large-scale sculptural applications, particularly when factors like logistics, long-term maintenance, and intricate design are paramount.

The Meticulous Manufacturing Process of a Fiberglass Statue

Creating a large-scale **fiberglass statue of liberty** or any complex fiberglass sculpture is a sophisticated multi-stage process that blends traditional artistry with advanced engineering. This ensures both aesthetic fidelity and structural integrity. The process typically involves:

1. Conceptualization & 3D Modeling

The journey begins with client vision, translated into detailed sketches, technical drawings, and precise 3D digital models (CAD/Rhino/ZBrush). This stage defines exact dimensions, proportions, and surface textures for the desired large fiberglass statue.

2. Sculpting (Clay/Foam/CNC)

A full-size master model is sculpted. This can be done traditionally with clay by skilled artisans, or for complex geometric forms and precision, a CNC machine carves the model from foam (e.g., polystyrene). This creates the exact physical representation of the final artwork.

3. Mold Creation

From the master model, a multi-piece mold is meticulously crafted. For high detail, a silicone rubber mold is often used for the inner layer, backed by a rigid fiberglass "mother mold" for structural support. For simpler forms, a direct fiberglass mold may be sufficient. The mold is critical for capturing every nuance of the original sculpture.

4. Fiberglass Layup (Laminating)

Once the mold is prepared and treated with a release agent, a colored gel coat (the outer protective layer) is applied. This layer provides the primary aesthetic finish and UV protection. Following this, layers of fiberglass mat or woven roving are saturated with thermosetting resin (polyester, vinyl ester, or epoxy) and carefully laid into the mold, building up thickness and strength. This is a critical step for structural integrity.

5. Curing & Demolding

The resin undergoes a chemical reaction, hardening the fiberglass layers. Once cured, the rigid fiberglass part is carefully separated from the mold. For large sculptures, multiple sections are typically molded and then assembled.

6. Assembly & Seam Finishing

Individual fiberglass sections are precisely joined together. Seams are reinforced from the inside with additional fiberglass layers, then carefully sanded, filled, and blended on the exterior to create a seamless surface, making the structure appear as a single, cohesive piece.

7. Internal Armature & Structuring

For large or structurally demanding pieces like a **fiberglass statue of liberty**, an internal steel armature (framework) is designed and integrated during or after the assembly phase. This framework provides critical structural support, especially against wind loads and seismic activity, ensuring stability and longevity.

8. Surface Preparation & Finishing

The entire surface is meticulously sanded smooth, prepped, and primed. This creates a perfect base for the final paint application. Artists then apply custom colors, textures, and patinas using high-quality automotive-grade paints, ensuring vibrant, durable, and weather-resistant finishes.

9. Quality Control & Inspection

Throughout the process, rigorous quality control checks are performed. This includes material inspection, dimensional accuracy, structural integrity (e.g., ultrasound testing for void detection), and finish quality. Adherence to standards like ISO 9001 (Quality Management) and ANSI (specific material performance) ensures a superior product.

10. Packaging & Shipping

The finished sculpture is securely packaged, often in custom crates, to prevent damage during transit. For monumental works, specialized logistics and heavy lifting equipment are employed for safe delivery to the installation site.

This detailed process ensures that each large fiberglass statue, whether it's an abstract art piece or a realistic animal sculpture, meets the highest standards of artistic expression and structural engineering. The emphasis on quality materials and adherence to recognized standards like ISO for production and ANSI for material strength ensures a long operational life, making them ideal for demanding environments such as public parks (resilience to wear and tear) or even industrial settings like petrochemical plants (corrosion resistance in harsh atmospheres).

Application Scenarios and Exemplary Cases

The versatility of fiberglass allows for its deployment across a multitude of sectors. Beyond purely aesthetic applications, its robust properties make it suitable for challenging environments:

- Public & Urban Spaces: From historical figures to contemporary art, **fiberglass statue of liberty** replicas, or abstract public art. For instance, many city beautification projects feature large, colorful fiberglass sculptures as landmarks.

- Theme Parks & Entertainment: Lifelike characters, elaborate sets, and monumental structures that are exposed to constant public interaction and varied weather conditions. Fiberglass's low weight allows for easier installation on existing structures.

- Commercial & Retail Environments: Branding elements, product replicas, and whimsical displays that capture attention. A well-placed large fiberglass buddha statue or a company mascot can become an iconic symbol.

- Museums & Exhibitions: Durable and accurate reproductions of historical artifacts or anatomical models.

- Educational Institutions: Custom mascots, motivational sculptures, or even interactive learning exhibits that require resilience and safety.

- Water & Wastewater Treatment: While not sculptural in the traditional sense, fiberglass's superior corrosion resistance is widely utilized in tanks, pipes, and covers in these industries, showcasing its material advantages.

- Marine & Coastal Areas: Its resistance to salt water and harsh marine environments makes it ideal for coastal installations or even components of maritime structures.

Case Study: Garden Decorative Life Size Fiberglass Elephant Sculptures

Our Garden Decorative Life Size Fiberglass Elephant Sculptures Resin Animal Sculpture For Sale exemplify the application of these advanced techniques. These majestic pieces are not only visually stunning but also engineered for durability. They are perfect for:

- Zoological Parks: Providing lifelike, robust representations that withstand environmental exposure and public interaction.

- Private Estates & Gardens: Adding a touch of grandeur and exotic beauty without the maintenance burden of living animals or heavy traditional materials.

- Commercial Lobbies & Hotels: Creating unforgettable first impressions with a grand, artistic statement piece.

- Educational Settings: As teaching aids for animal studies or environmental awareness, offering a tangible, large-scale representation.

These sculptures are designed to resist UV degradation, moisture, and temperature fluctuations, ensuring their vibrant appearance and structural integrity for decades. Their relatively lighter weight compared to concrete or stone alternatives also simplifies transportation and installation, leading to significant cost savings for clients.

Choosing the Right Manufacturer: Expertise, Authority, and Trust

When investing in a large fiberglass statue, particularly for complex or iconic designs like a **fiberglass statue of liberty**, selecting the right manufacturer is paramount. A reputable manufacturer stands out by demonstrating:

- Expertise (E): Deep understanding of materials science, mold-making, lamination techniques, and structural engineering. They can advise on the best resin systems (e.g., isophthalic polyester for water resistance, epoxy for maximum strength), gel coat applications, and internal armature design for specific environmental conditions (e.g., wind loads in coastal areas).

- Experience (E): A proven track record with a diverse portfolio of successful large-scale projects. They should be able to provide case studies, client testimonials, and demonstrate problem-solving capabilities from past installations. This includes experience with complex logistics and on-site assembly.

- Authoritativeness (A): Industry certifications (e.g., ISO 9001 for Quality Management Systems, ASTM standards for material testing), affiliations with professional associations, and collaborations with structural engineers or renowned artists. Longevity in the industry (e.g., "over 20 years in business") and a strong network of trusted suppliers also signify authority.

- Trustworthiness (T): Transparent pricing, clear communication, comprehensive warranties, and dedicated customer support post-installation. They should provide detailed proposals, project timelines, and be open to facility visits or third-party inspections.

Customization Solutions

A top-tier fiberglass manufacturer offers extensive customization. This includes:

- Scale and Proportion: Replicating designs from miniatures to monumental. For example, creating a 50-foot tall **fiberglass statue of liberty** for a theme park.

- Surface Finish & Texture: From high-gloss automotive finishes to matte, textured, or even faux-material effects (e.g., imitation bronze, stone, or wood).

- Color Matching: Precise color matching to corporate branding or artistic vision using durable pigments and paints.

- Integration of Features: Incorporating LED lighting, water features, sound systems, or interactive elements directly into the sculpture design.

- Structural Enhancements: Designing for specific wind loads, seismic zones, or public interaction levels, including anti-graffiti coatings and impact resistance.

Delivery, Warranty, and Support

Reputable manufacturers typically provide:

- Delivery Period: Varies significantly by project complexity and size, usually ranging from 8-16 weeks for custom large fiberglass statues after design approval. Expedited options may be available for a premium.

- Warranty: A standard warranty period of 1 to 5 years against manufacturing defects, material failure (e.g., delamination), and significant fading/peeling of the finish. Extended warranties may be offered.

- Customer Support: Comprehensive pre-sale consultation, ongoing project updates, and robust post-installation support including maintenance guidelines, cleaning recommendations, and repair services for accidental damage.

Frequently Asked Questions (FAQ)

Fiberglass, or Fiber Reinforced Polymer (FRP), is a composite material made of glass fibers embedded in a polymer resin matrix (typically polyester, vinyl ester, or epoxy). It's known for its high strength-to-weight ratio, durability, and corrosion resistance.

Properly manufactured large fiberglass statues with UV-resistant gel coats and automotive-grade paints can last 20-30+ years outdoors, even in harsh weather conditions, with minimal maintenance. Their resistance to rust, rot, and pest damage makes them highly durable.

Yes, fiberglass offers immense flexibility in scale. From small replicas to monumental structures exceeding 50 feet, the molding process allows for virtually any size, limited only by transport and installation logistics.

Key inspection standards include adherence to ISO 9001 for quality management during manufacturing. Material properties might be tested against ASTM standards (e.g., ASTM D2583 for Barcol Hardness, ASTM D638 for Tensile Properties) to ensure material strength and consistency. Visual inspections also confirm surface finish and dimensional accuracy.

For large pieces, an internal steel armature (skeleton) is engineered and integrated within the fiberglass shell. This framework is designed to withstand environmental forces like wind loads and seismic activity, providing essential structural stability. Finite Element Analysis (FEA) software is often used to model and optimize these internal structures.

Compared to traditional materials like stone or bronze, fiberglass sculptures are significantly lighter, making transportation less complex and costly. Installation often requires less heavy equipment and simpler foundations, reducing overall project timelines and expenses.

Maintenance is minimal. Regular cleaning with mild soap and water is usually sufficient to remove dirt and grime. Periodically, depending on exposure, a fresh clear coat or wax application can further protect the surface and enhance its longevity. Repairs for minor damage are generally straightforward.

Conclusion: The Future is in Fiberglass

The evolution of fiberglass technology has positioned it as the material of choice for large-scale sculptures, offering a compelling blend of artistic freedom, engineering precision, and long-term value. Whether it's replicating an iconic **fiberglass statue of liberty**, commissioning a bespoke large fiberglass Buddha statue, or creating enchanting large fiberglass statues for public spaces, this versatile composite material delivers exceptional results.

Its superior performance in terms of strength, weight, corrosion resistance, and moldability ensures that fiberglass will continue to dominate the market for monumental art and architectural elements. By partnering with experienced and authoritative manufacturers who adhere to stringent quality standards, clients can realize their grandest artistic visions with confidence, knowing their investment is durable, sustainable, and truly impactful for generations to come.

References:

- [1] Composites Industry Forum. "The Role of FRP in Modern Sculpture and Architecture." (Accessed via Industry Reports section, 2023). www.compositesworld.com

- [2] Journal of Advanced Materials. "Mechanical Properties and Durability of Fiber Reinforced Polymers for Outdoor Applications." Vol. 45, No. 2, pp. 123-138 (2022). www.tandfonline.com/journals/yadm20

- [3] Grand View Research. "Fiber Reinforced Polymer Composites Market Size, Share & Trends Analysis Report." (2021). www.grandviewresearch.com

- [4] ISO Standards. "ISO 9001: Quality management systems." www.iso.org/iso-9001-quality-management.html

Post time:Aug . 07, 2025 08:00