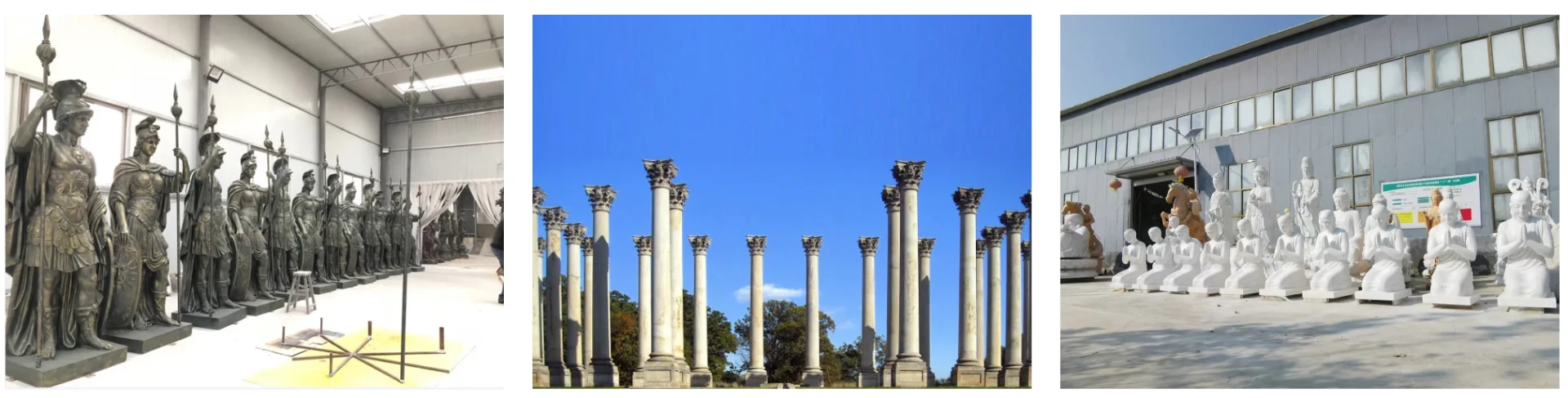

Metal Statue Manufacturer Bronze Casting Techniques

Mastering the Art of Bronze Sculpture Production:As a premier metal statue manufacturer, Quyang Tengyun Carving combines ancient bronze casting techniques with modern technology. Our statue manufacturer expertise spans multiple casting methods, while our statue supplier services deliver these timeless artworks globally with museum-quality finishes.

Traditional Lost-Wax Casting by Metal Statue Manufacturer

Our metal statue manufacturer process includes:

• Original clay model creation by master sculptors

• Precision silicone mold making

• Multiple wax duplicate production

• Ceramic shell investment casting

• Bronze pouring at 2100°F (1150°C)

• Chasing and metal finishing

Modern Casting Innovations from Statue Manufacturer

The statue manufacturer facility utilizes:

• 3D scanning for digital model preservation

• CAD-assisted enlargement/reduction

• Robotic arm carving for large reproductions

• Vacuum-assisted casting for thin walls

• X-ray inspection for internal quality

Material Expertise as Bronze Statue Supplier

Our statue supplier services guarantee:

• Authentic bronze alloys (90% copper mix)

• Silicon bronze for outdoor durability

• Custom patina chemical formulations

• Marine-grade bronze for coastal installations

• Structural steel armatures for stability

Surface Finishing Techniques

The metal statue manufacturer offers:

• Traditional chemical patination

• Gold/silver leaf gilding

• Polished mirror finishes

• Textured hammered effects

• Artificial weathering for antique looks

• Clear protective wax coatings

Quality Control Processes

Every statue manufacturer piece undergoes:

• Metallurgical composition testing

• Wall thickness verification

• Stress point reinforcement

• Outdoor durability testing

• Artisan final inspection

• Conservation documentation

Global Installation Capabilities

Our statue supplier services include:

• Professional art crating

• Climate-controlled shipping

• On-site assembly

• Foundation engineering

• Lighting consultation

• Maintenance programs

Metal Statue Manufacturer FAQs

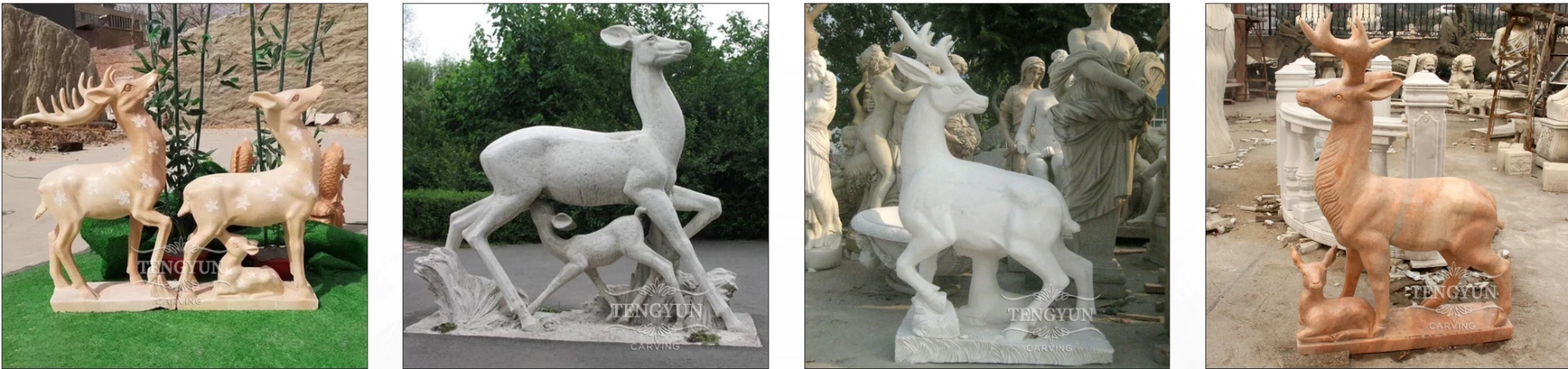

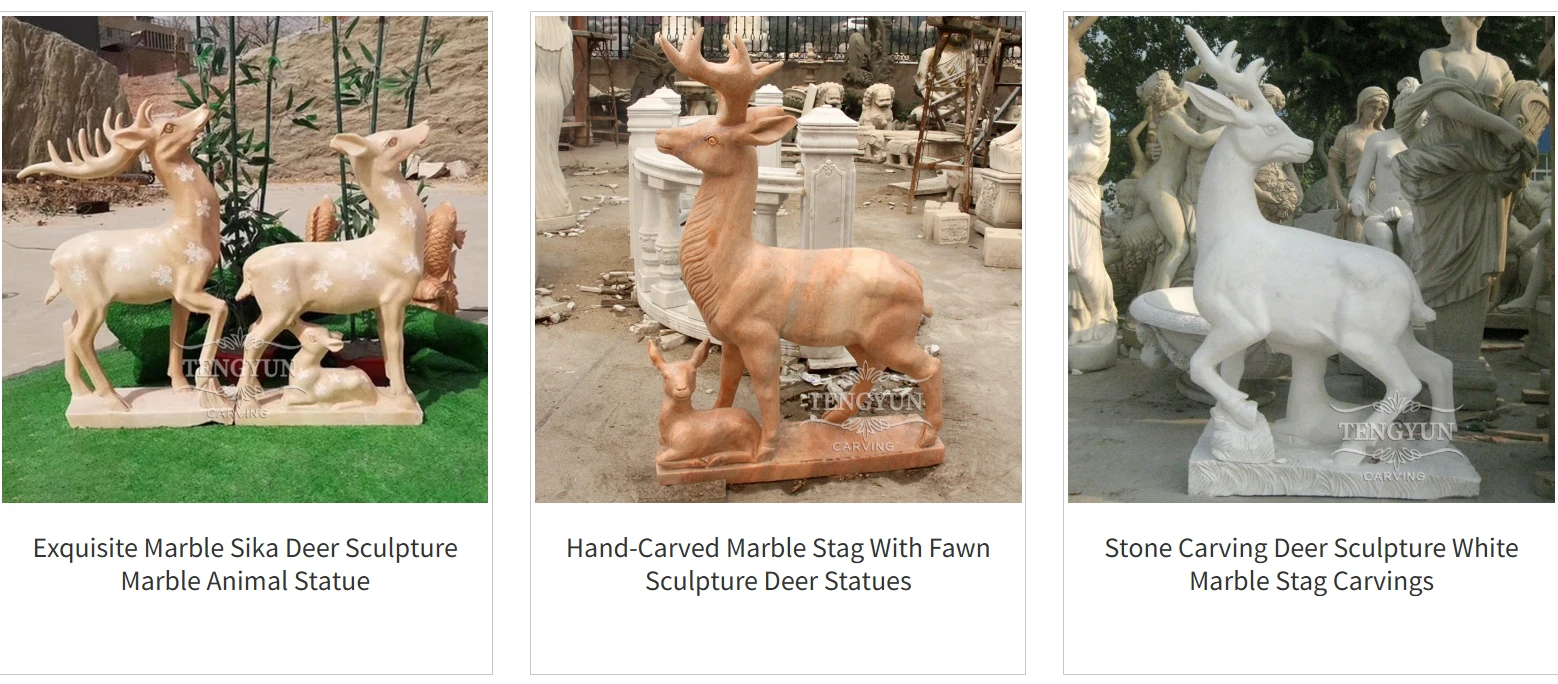

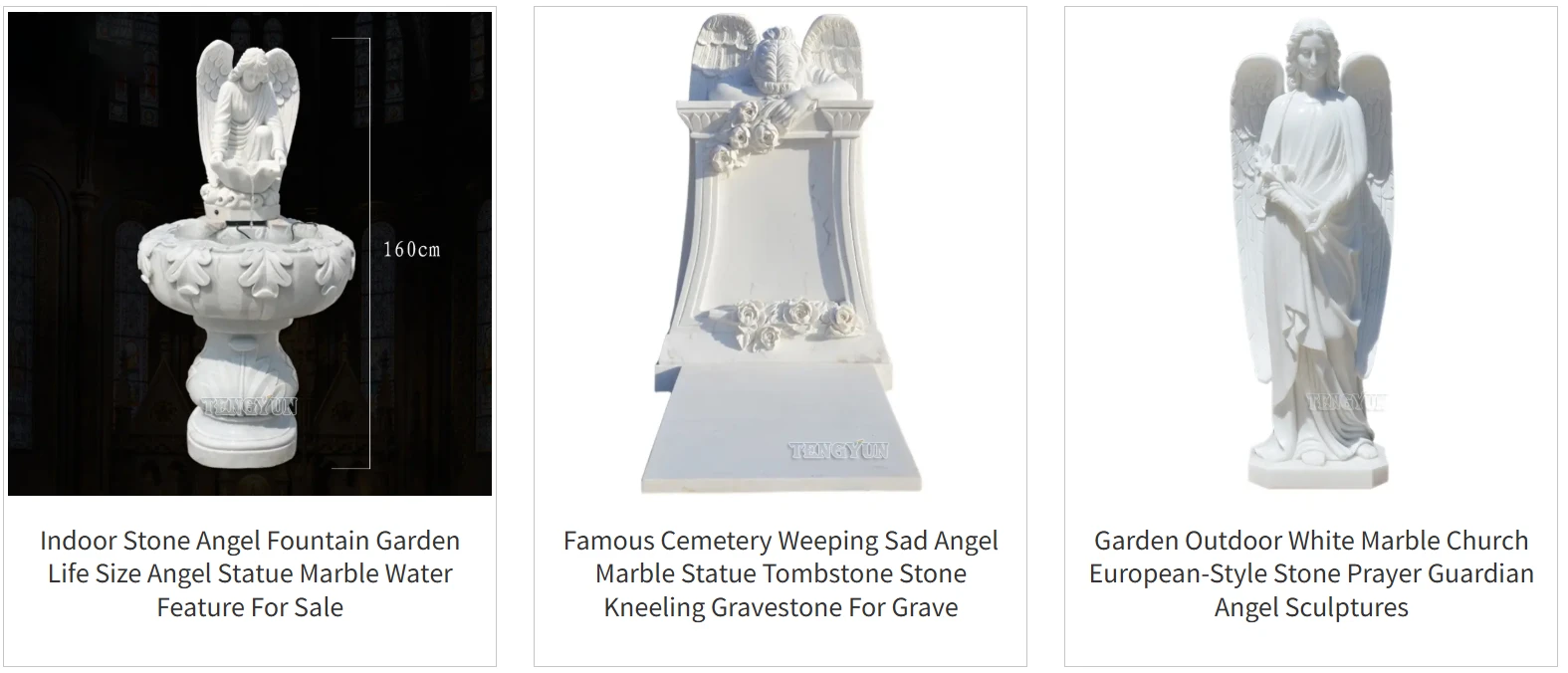

Q: What materials do statue manufacturer teams commonly use besides metal, and how do they choose the right material for a project?

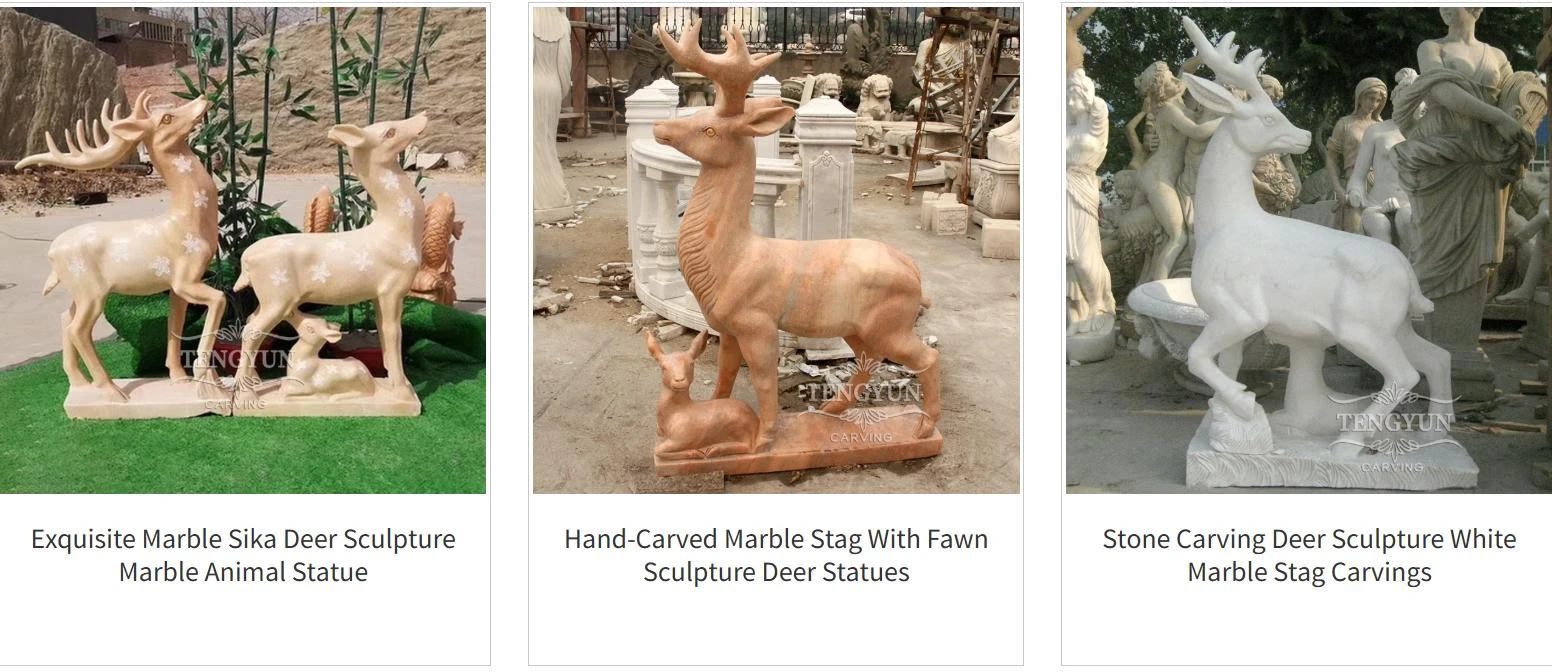

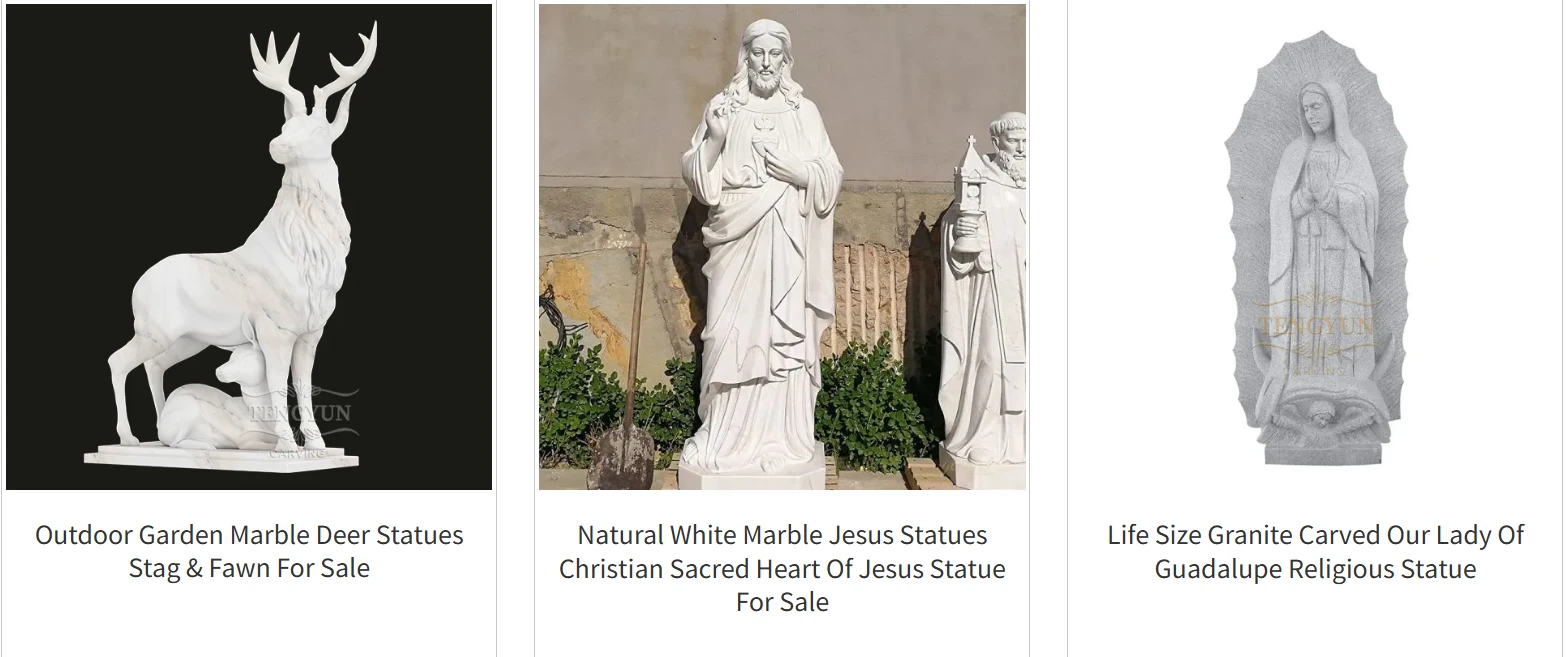

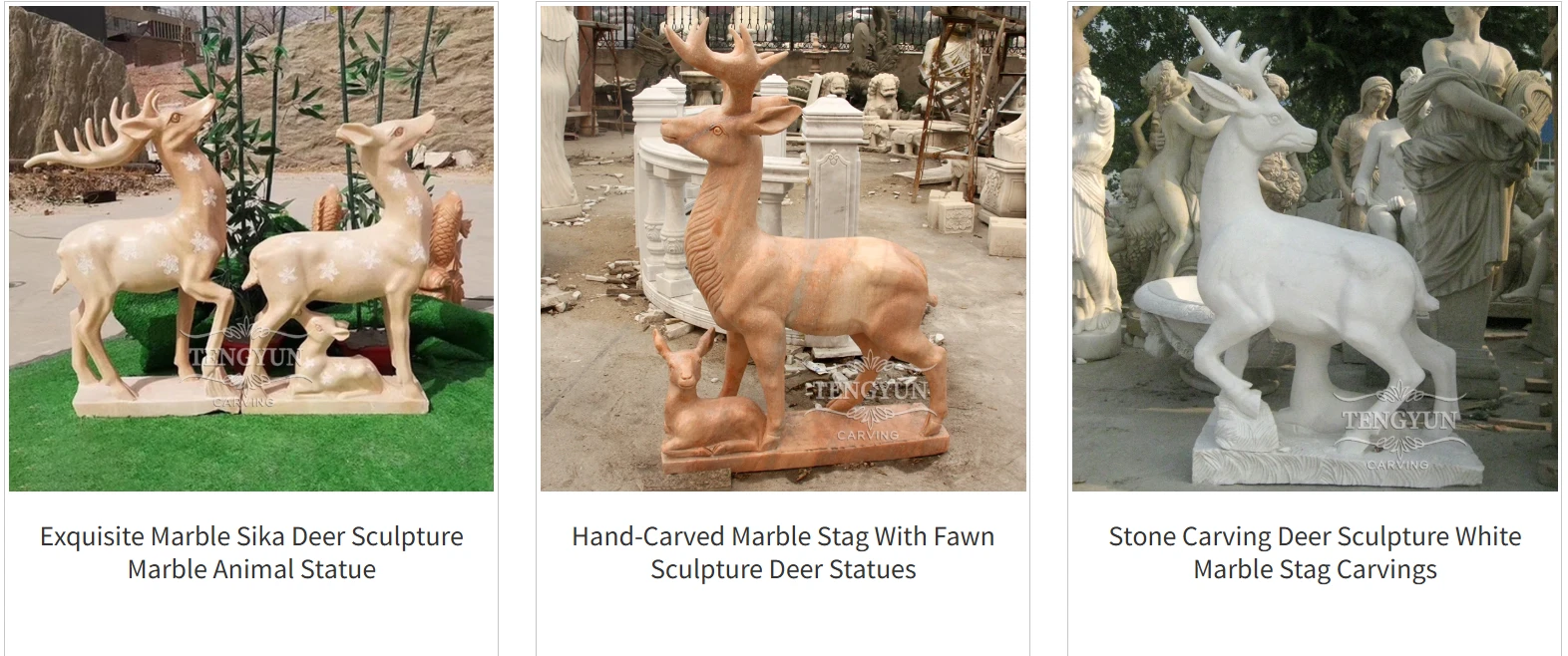

A: Statue manufacturer teams work with diverse materials beyond metal, including stone (marble, granite), resin, ceramic, and fiberglass. Material selection depends on the statue’s purpose: outdoor pieces often use weather-resistant options like bronze (metal), granite (stone), or fiberglass (lightweight and durable). Indoor statues may feature marble (for elegance) or resin (cost-effective for replicas). For large-scale projects, metal (steel, aluminum) offers structural strength, while ceramic or resin suits smaller, detailed pieces. They also consider client budget—resin is more affordable than bronze—and aesthetic goals, matching material texture (e.g., polished marble vs. rustic stone) to the design’s style.

Q: How does a statue supplier ensure the quality of mass-produced statues compared to custom, one-of-a-kind pieces?

A: A statue supplier maintains quality across mass-produced and custom statues through standardized processes. For mass production, they use molds (for resin, metal casting) to ensure consistency in size and design, with automated checks for defects (e.g., air bubbles in resin). Each piece undergoes manual inspection for finish (painting, polishing) to meet brand standards. Custom, one-of-a-kind statues involve more hands-on oversight: artisans track progress through stages (carving, welding) and conduct detailed reviews with clients at key milestones. Both types adhere to material-specific quality benchmarks (e.g., metal thickness, stone density) and often include quality certificates, ensuring durability and craftsmanship regardless of production scale.

Q: What customization options are available for metal statues from a metal statue manufacturer?

A: A metal statue manufacturer offers extensive customization, starting with metal type (bronze, stainless steel, iron, aluminum) to match durability and aesthetic needs. Clients can choose finishes: patinas (green for bronze, rust for iron) for aged looks, polished (shiny stainless steel) for modern styles, or painted coatings for color matching. Design-wise, they accommodate custom sizes (from miniatures to monumental), intricate details (engravings, 3D features), and thematic elements (mythological figures, corporate logos). Some offer mixed materials (e.g., metal with stone bases) and structural modifications (mounting brackets for outdoor installation). Prototypes or 3D models are often provided to approve designs before full production.

Q: How do statue supplier services handle shipping for fragile or oversized statues to prevent damage?

A: Statue supplier services use specialized shipping methods for fragile or oversized statues. Fragile pieces (ceramic, marble) are wrapped in acid-free tissue, foam, or bubble wrap, then placed in custom wooden crates with internal bracing to prevent movement. Oversized metal or stone statues may require freight shipping with flatbed trucks, secured with straps and padded supports. Climate-controlled containers protect against temperature/humidity damage (critical for metal with patinas or painted finishes). Suppliers often partner with art transport specialists, providing insurance coverage for loss or damage. For installation, they may coordinate with local teams to unload and position the statue, ensuring safe handling from warehouse to final location.

Q: What maintenance do metal statues from a metal statue manufacturer require to preserve their appearance over time?

A: Metal statues from a metal statue manufacturer need regular maintenance to stay intact. Bronze statues benefit from annual cleaning with a soft cloth and mild soap to remove dirt, followed by a wax coating to protect the patina (avoid harsh chemicals that can strip the finish). Stainless steel statues require periodic polishing with a metal cleaner to maintain shine and prevent fingerprint buildup. Iron or steel statues, prone to rust, should be inspected for corrosion—treat small rust spots with sandpaper and touch-up paint, and apply a rust-inhibiting coating every 2–3 years, especially for outdoor pieces. Outdoor metal statues also need drainage checks to prevent water pooling in crevices, which can accelerate wear. Following the manufacturer’s care guide ensures longevity, even in harsh weather.

Post time:aug . 27, 2025 14:50