Exquisite Christ Sculpture: Hand-Carved Marble Statues

Industry Trends in Sacred Sculpture Fabrication

The global market for sacred sculptures, particularly christ sculpture, is undergoing significant evolution driven by technological advancements and evolving aesthetic preferences. While traditional craftsmanship remains paramount, the integration of digital tools is enhancing precision and expanding design possibilities. There's a growing demand for bespoke pieces that reflect specific theological interpretations and architectural contexts, moving beyond mass-produced items. Clients, ranging from ecclesiastical institutions to private collectors, increasingly seek master-crafted works that not only serve a devotional purpose but also act as enduring artistic investments.

A key trend is the emphasis on material authenticity and provenance. High-grade natural marble, particularly Italian Carrara and Greek Thassos, continues to be the material of choice for its unparalleled purity, durability, and classic aesthetic. This preference underscores a long-term investment perspective, as these materials ensure the longevity and aesthetic integrity of the artwork for centuries. Furthermore, sustainability in sourcing and ethical labor practices are becoming critical considerations for discerning buyers in the B2B sector, reflecting broader corporate social responsibility initiatives. The market for large-scale outdoor installations, including monumental christ statues, is also expanding, necessitating advanced engineering and weather-resistant finishing techniques.

Moreover, the rise of global commerce has made expert carving houses accessible worldwide, allowing for greater customization and competitive pricing, while maintaining uncompromised quality. The ability to collaborate virtually through detailed CAD renderings and 3D models during the design phase has streamlined the commissioning process, ensuring client specifications are met with exceptional accuracy before physical production commences. This blending of ancient artistry with modern project management defines the leading edge of the sacred sculpture industry.

Manufacturing Process: Precision in Stone

The creation of a monumental christ sculpture is a meticulous, multi-stage process that fuses traditional artistry with modern engineering. This ensures not only the artistic integrity but also the structural longevity and compliance with stringent quality standards.

Process Flow: From Quarry to Masterpiece

- Material Sourcing & Selection: Premium natural marble, such as Carrara Bianco, Thassos White, or Statuario, is meticulously selected from reputable quarries. Emphasis is placed on the stone's purity, veining consistency, crystalline structure, and absence of significant geological flaws. This ensures uniform material integrity critical for large-scale sculptures and adherence to aesthetic benchmarks for a marble statue god.

- Conceptual Design & Prototyping: Initial client concepts are translated into detailed 2D drawings and advanced 3D CAD models. For complex designs, a physical clay or resin maquette (scale model) is often produced to refine proportions and intricate details, allowing for precise technical planning and client approval before stone carving begins.

- Block Preparation & Initial Carving (Roughing): Large marble blocks are carefully cut to approximate dimensions. Modern techniques may involve computer numerical control (CNC) machining to execute the initial roughing stages based on 3D models, removing significant bulk of material with high precision, thus accelerating the process and reducing material waste while preserving the core artistic vision. This initial stage defines the overall form of the christ sculpture.

- Detailed Carving & Shaping: Highly skilled artisans then take over, employing traditional hand-carving techniques. Using an array of chisels, mallets, and specialized tools, they meticulously sculpt the intricate features, drapery, and anatomical details. This phase demands profound artistic skill and an intimate understanding of marble's properties.

- Sanding & Polishing: Once the carving is complete, the sculpture undergoes multiple stages of sanding using progressively finer abrasives. This process refines the surface, removing tool marks and preparing the stone for its final finish. Polishing is then applied, often using natural waxes or diamond pads, to achieve the desired luster, from a soft matte finish to a high-gloss sheen that enhances the marble's natural translucency.

- Quality Control & Finishing: Each sculpture undergoes rigorous quality inspection at various stages. Final inspection verifies dimensional accuracy, artistic fidelity, surface finish, and structural integrity. Any minor imperfections are addressed. For outdoor installations, specific sealants may be applied to enhance weather resistance and protect against environmental degradation.

- Packaging & Logistics: Sculptures are professionally crated using custom-built wooden frameworks, often incorporating internal bracing and shock-absorbing materials, to ensure safe transit globally.

Technical Specifications & Standards

Our fabrication processes adhere to international quality management systems, including ISO 9001:2015 for quality control and ISO 14001:2015 for environmental management. All materials are tested for physical properties such as compressive strength, flexural strength, and water absorption rates, ensuring the longevity and structural stability of the finished piece.

- Material Durability: Marble specimens undergo ASTM C97 (Absorption and Bulk Specific Gravity) and ASTM C170 (Compressive Strength) testing. Typical marble compressive strength ranges from 70-120 MPa, ensuring resistance to significant loads.

- Finish & Weather Resistance: Specialized finishes and sealants are employed for outdoor installations, rigorously tested for UV resistance, freeze-thaw cycles (ASTM C666), and chemical resistance, thereby ensuring a service life exceeding 100 years even in challenging climates.

- Dimensional Accuracy: Utilizing advanced laser scanning and measurement techniques, critical dimensions are maintained within a tolerance of ±2mm for large-scale projects, surpassing ANSI A137.1 standards for precision.

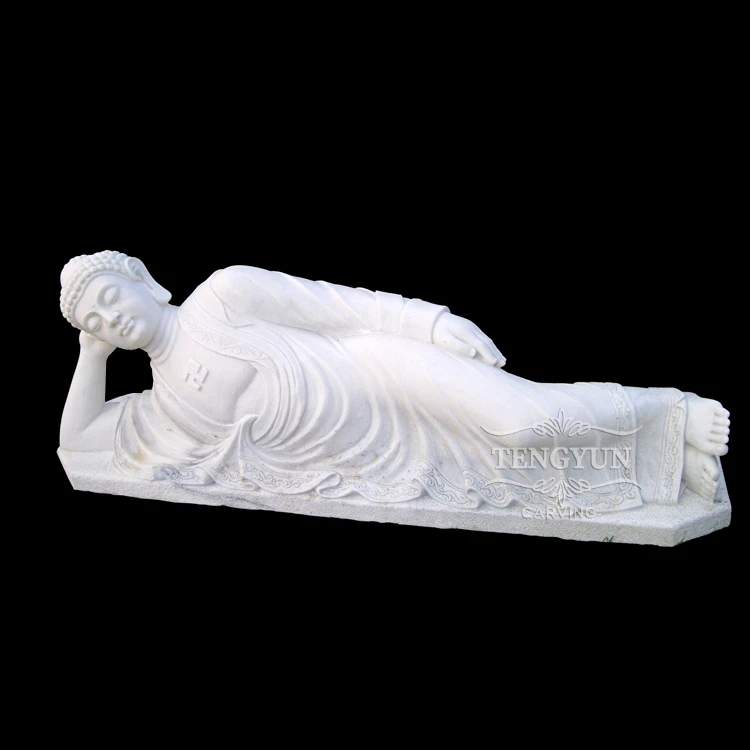

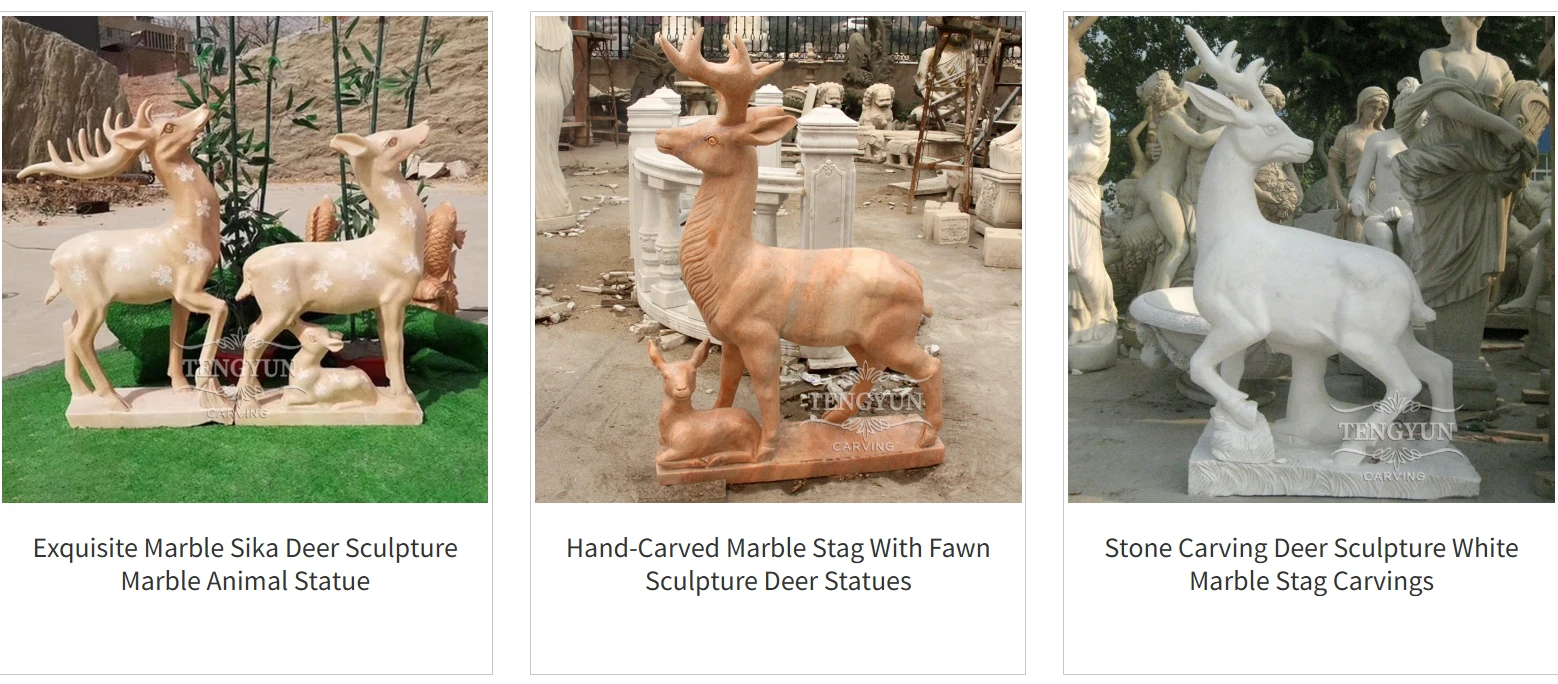

Detailed carving of a Sacred Heart of Jesus statue, exemplifying fine artistry in christ sculpture.

Target Industries & Advantages

- Ecclesiastical Institutions: Churches, cathedrals, basilicas, monasteries requiring high-quality liturgical art. Advantages include energy saving (natural light reflection), corrosion resistance (to environmental factors), and minimal maintenance due to marble's inherent properties.

- Architectural Firms & Developers: Projects involving public spaces, memorial parks, spiritual centers, and luxury residential estates seeking iconic artistic elements like statues of christ around the world.

- Private Collectors & Art Galleries: Individuals and institutions commissioning unique works of sacred art for display or investment.

Technical Specifications: White Marble Jesus Statue

Our Religious Church White Marble Jesus Statue (Sacred Heart of Jesus) is engineered for both aesthetic brilliance and enduring performance. The following table details the key parameters and specifications of this exquisite christ sculpture.

| Parameter | Specification | Technical Standard |

|---|---|---|

| Product Name | Religious Church White Marble Jesus Statue Sacred Heart of Jesus Statues For Sale | Client-Specific Request (CSR) |

| Primary Material | Grade A Natural White Marble (e.g., Carrara, Thassos, Volakas) | ASTM C503 (Standard Specification for Marble Dimension Stone) |

| Standard Heights Available | 150 cm, 180 cm, 200 cm, 250 cm (Customizable) | ISO 2768-1 (General Tolerances) |

| Weight (for 180cm height) | Approx. 750 kg - 900 kg (depending on marble density) | Calculated Mass, Verified via Digital Scales |

| Surface Finish | High Polished, Honed, or Antique Finish (Client Preference) | Visual Inspection against Reference Samples |

| Compressive Strength (Marble) | 90 - 110 MPa | ASTM C170 |

| Water Absorption (Marble) | Typically < 0.2% by weight | ASTM C97 |

| Density (Marble) | 2700 - 2800 kg/m³ | ASTM C97 |

| Service Life (Outdoor) | 100+ Years (with proper installation & maintenance) | Accelerated Weathering Tests (ASTM G154, G155) |

| Application Environment | Indoor & Outdoor (Churches, Cathedrals, Gardens, Memorials) | Environmental Suitability Assessment |

Application Scenarios & Advantages

The versatility and inherent qualities of marble christ statues make them suitable for a broad spectrum of prestigious applications. Our expertise extends to ensuring optimal integration into diverse architectural and environmental contexts.

- Cathedral & Church Interiors: As central devotional pieces, marble sculptures enhance the spiritual ambiance. The natural reflectivity of polished marble contributes to interior luminescence, reducing the need for artificial lighting (energy saving) and providing an everlasting aesthetic.

- Outdoor Memorial Gardens & Courtyards: Our sculptures are engineered to withstand environmental exposure. The natural resistance of high-density marble to weathering, UV radiation, and biological growth ensures long-term integrity (corrosion resistance) without significant degradation, making them ideal for lasting tributes.

- Monasteries & Retreat Centers: Creating focal points for contemplation and prayer. The tactile and visual presence of a meticulously carved marble piece offers a profound sensory experience, fostering spiritual engagement.

- Public Art Installations: For urban developments or historical sites, large-scale statues of christ around the world serve as cultural landmarks, drawing visitors and contributing to the aesthetic value of public spaces, ensuring minimal maintenance for civic authorities.

A magnificent life-size white marble statue of Jesus, ready for installation in a distinguished ecclesiastical setting, showcasing superior artistry and material quality of christ sculpture.

Technical Advantages of Our Marble Sculptures

Our commitment to engineering excellence and traditional craftsmanship provides distinct technical advantages for our B2B clients seeking premium christ sculpture solutions.

- Superior Material Integrity: We utilize only ethically sourced, high-density natural marble, validated by geological surveys and material testing. This ensures minimal porosity, high compressive strength (typically 90-110 MPa), and exceptional resistance to environmental degradation, outperforming composite materials or lower-grade stones.

- Advanced Carving Precision: The integration of 3D scanning and CNC roughing with master artisan hand-finishing allows for unparalleled accuracy in replicating complex designs while retaining the soulful essence of hand-sculpted art. This hybrid approach ensures dimensional conformity and minimizes waste, improving project efficiency.

- Optimized Durability & Longevity: Through meticulous material selection and the application of tested sealants for outdoor pieces, our sculptures exhibit superior resistance to UV exposure, acid rain, and freeze-thaw cycles. This significantly extends the operational service life, minimizing lifecycle costs for institutions.

- Aesthetic Consistency & Fidelity: Our rigorous quality control protocols, including photographic documentation at each production stage, guarantee that the final product adheres precisely to approved designs and material specifications. This ensures consistency for multi-piece installations or replications.

- Structural Engineering for Large Scales: For monumental christ statues, internal stainless steel armatures and engineered base anchoring systems are incorporated as required, designed by structural engineers to ensure stability and safety under various environmental loads (e.g., wind, seismic activity). These designs comply with local building codes and international structural integrity standards.

Vendor Comparison: Choosing Your Sacred Art Partner

Selecting a supplier for a significant project like a marble statue god or a complex devotional piece requires careful evaluation of several key criteria beyond initial cost. This comparison highlights why our integrated approach often provides superior value and reliability for B2B clients.

| Feature/Criterion | Our Offering | Typical Competitor (General) |

|---|---|---|

| Material Quality & Sourcing | Certified Grade A Natural Marble (e.g., Carrara, Thassos), verified provenance, ethical sourcing. | May use lower-grade marble, composite stone, or unverified origin materials. |

| Craftsmanship & Expertise | Master artisans (20+ years experience) combined with precision CNC for roughing; artistic integrity paramount. | Varies widely; often relies solely on hand carving (slower) or excessive CNC (less artistic detail). |

| Design & Customization | Full 3D modeling, CAD rendering, maquettes, unlimited revisions until client satisfaction. Fully bespoke designs. | Limited customization options, reliance on existing molds/templates, fewer design review stages. |

| Quality Assurance & Standards | ISO 9001:2015, multi-stage QC, material testing (ASTM, EN), detailed photographic progress reports. | Informal QC, basic visual checks, limited documentation, no specific material certifications. |

| Structural Engineering (for large pieces) | Integrated internal armatures, engineered base solutions, compliance with local building codes. | Often overlooked or simplistic, potentially compromising long-term stability and safety. |

| Logistics & Installation Support | Professional crating, global shipping management, installation consultation, site-specific guidance. | Basic crating, client responsible for complex logistics and installation. |

| Warranty & After-Sales | Comprehensive warranty (e.g., 5-10 years on material/workmanship), dedicated support. | Limited or no formal warranty, reactive customer service. |

Customized Solutions for Unique Vision

Understanding that each client possesses a unique vision, we specialize in providing fully customized solutions for any christ sculpture project. Our process is designed to translate conceptual ideas into tangible masterpieces with precision and artistic integrity.

- Tailored Design & Prototyping: We engage in extensive consultation to capture specific aesthetic, theological, and architectural requirements. This includes producing detailed blueprints, 3D digital models, and physical maquettes for design approval, ensuring every curve and expression aligns with the client's expectation.

- Material & Finish Selection: Clients can choose from a broad palette of premium natural marbles (e.g., Carrara, Thassos, Sivec, Statuario) and select desired finishes—from high-polish to matte, antique, or bespoke textures—to perfectly match the intended environment and artistic effect.

- Scalability & Site Integration: Whether a life-size statue for an altar or a monumental outdoor installation, we engineer solutions to fit specific dimensions and site conditions. This includes expert advice on foundation preparation, structural support, and long-term maintenance protocols specific to the chosen material and environment.

- Integration of Historical & Cultural Elements: Our artisans are adept at incorporating specific historical iconography, regional artistic styles, or cultural nuances into the sculpture, ensuring a piece that is not only beautiful but also deeply resonant with its intended audience and context.

Application Case Studies

Our portfolio showcases successful collaborations with diverse institutions, demonstrating our capability to deliver iconic christ statues and other sacred art.

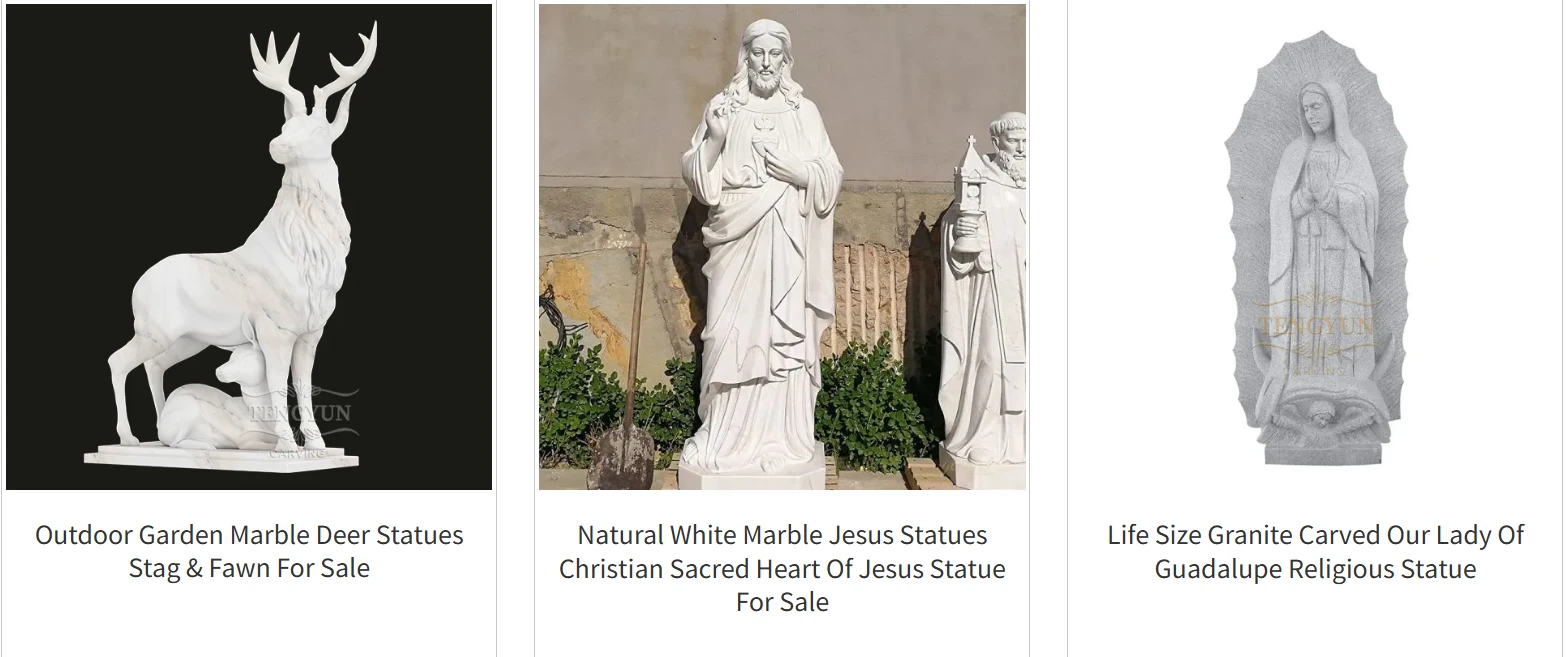

Case Study 1: Grand Cathedral Renovation – Sacred Heart of Jesus

Client: St. Michael's Archdiocesan Cathedral, Rome, Italy

Challenge: To replace a weathered limestone statue of the Sacred Heart of Jesus in the main narthex with a more durable and aesthetically superior marble piece that harmonized with the cathedral's historic Baroque architecture, while ensuring minimal disruption during installation.

Solution: We meticulously crafted a 2.5-meter tall christ sculpture from premium Carrara Statuario marble. The design replicated the original iconography but with enhanced anatomical precision and drapery detail. Utilizing 3D scanning of the original and advanced CAD modeling, we ensured perfect dimensional fit. The sculpture was finished with a honed polish to match the existing interior marble, and was engineered with an internal stainless steel armature for long-term structural integrity.

Outcome: The project was completed within budget and schedule. The new marble sculpture received widespread acclaim for its exquisite craftsmanship and luminous presence, becoming a focal point of devotion. The Cathedral noted a significant reduction in anticipated maintenance costs compared to the previous limestone piece, validating the choice for a higher-grade material with superior weather resistance for interior atmospheric variations.

Case Study 2: International Marian Shrine – Our Lady of Grace Courtyard

Client: Sanctuary of Our Lady of Grace, Fatima, Portugal

Challenge: To create several large-scale devotional marble figures, including a prominent marble statue god figure of Christ, for an outdoor courtyard in a region experiencing high sun exposure and occasional heavy rainfall. Durability and consistent aesthetic quality across multiple pieces were critical.

Solution: We provided three bespoke 2-meter statues carved from pure Thassos White marble, renowned for its minimal porosity and extreme weather resistance. Each piece underwent a specialized anti-UV and hydrophobic sealant application. Our project management included detailed packaging and international logistics, ensuring safe delivery and on-site technical consultation for installation.

Outcome: The statues were flawlessly installed and have maintained their pristine condition over several years, resisting discoloration and erosion. The client praised the consistent quality of craftsmanship across all pieces and the proactive support throughout the project, reinforcing the shrine's status as a site of profound beauty and devotion.

A beautifully sculpted Sacred Heart of Jesus statue, showcasing the delicate details and pristine finish achievable with high-grade white marble, a perfect example of exquisite christ sculpture.

Frequently Asked Questions (FAQ)

Q: What materials are typically used for a christ sculpture?

A: We primarily use high-grade natural marbles such as Carrara White, Thassos White, Volakas, and Statuario. These materials are chosen for their superior aesthetic qualities, durability, and historical significance in sacred art. Bronze and other natural stones can also be utilized upon request for specific project requirements.

Q: How long does the fabrication process take for a custom statue?

A: The lead time varies significantly based on the sculpture's complexity, size, and material availability. For a typical life-size marble christ sculpture (e.g., 180cm), the process from design approval to final carving and polishing usually takes 8-12 weeks. Large-scale or highly intricate projects may require 4-6 months. We provide a detailed project timeline upon design finalization.

Q: What are the packaging and shipping procedures for international orders?

A: All sculptures are custom-crated in robust wooden boxes, specifically designed to protect against shock and vibration during transit. Internal foam padding and bracing ensure secure positioning. We manage all international shipping logistics, including customs documentation, using reputable freight forwarders. Shipping typically occurs via sea freight for large items, with air freight options available for expedited delivery.

Q: Do you provide installation services or guidance?

A: While we do not typically provide on-site installation teams directly, we offer comprehensive installation guidance and technical support. This includes detailed structural drawings, recommended anchoring systems, and best practices for handling and placement. For highly complex installations, we can recommend experienced local contractors or provide a supervising engineer.

Q: What is your warranty policy for these sculptures?

A: We offer a 10-year structural warranty on all natural marble sculptures, covering defects in material and workmanship under normal use and recommended maintenance. This warranty reflects our confidence in the quality of our materials and the expertise of our artisans. Specific details are outlined in our contractual agreements.

Lead Time, Fulfillment & Support

Our streamlined process ensures efficient project management from initial inquiry to final delivery.

-

Lead Time:

- Design & Approval: 2-4 weeks (depending on complexity and revisions).

- Fabrication (standard size): 8-12 weeks for carving, finishing, and QC.

- Fabrication (large/complex): 16-24 weeks.

- Shipping (sea freight): 4-8 weeks depending on destination.

- Fulfillment Process: Upon final payment and quality approval (documented with high-resolution photographs/videos), your christ sculpture will be expertly crated. We handle all logistics, providing tracking information and proactive communication until successful delivery.

- Warranty Commitments: A comprehensive 10-year warranty against material and manufacturing defects. This warranty excludes damage from improper installation, lack of maintenance, or acts of nature beyond reasonable expectation.

- Customer Support: Our dedicated project managers provide continuous support from initial consultation through post-installation. Clients have direct access to our technical team for any inquiries regarding maintenance, restoration, or further customization. We pride ourselves on responsive and knowledgeable service, reflecting our commitment to long-term client relationships.

Authoritative References

- ISO 9001:2015. Quality management systems — Requirements. International Organization for Standardization.

- ASTM International. Standard Test Method for Compressive Strength of Natural Building Stone (C170). ASTM Committee C18 on Dimension Stone.

- National Stone Institute. (2019). Dimension Stone Design Manual. 8th Edition.

- Ashurst, J., & Dimes, F. G. (1998). Conservation of Building and Decorative Stone. Butterworth-Heinemann.

- Penny, N. (1993). The Materials of Sculpture. Yale University Press.

Post time:8 сар . 27, 2025 08:00